Lincoln Electric Auto-Darkening Variable Shade Welding Helmet with Grind Mode Fierce Red Graphic Pattern Model K3063-1 Only 119. Although this can create a solid weld using a weave pattern can be beneficial for wider joints and vertical welds.

Welding Vertically Mig Welding Forum

Liquid hydrogen has been used as a fuel in space technology for several decades.

. You simply perform a straight stringer bead. MIG Welding Wire for TIG Welding. Welding is a fabrication process that joins materials usually metals or thermoplastics by using high heat to melt the parts together and allowing them to cool causing fusionWelding is distinct from lower temperature techniques such as brazing and soldering which do not melt the base metal parent metal.

However hydrogen liquefies at 2529C 423F and. It spreads out the filler metal more resulting in a flatter bead. Janes The latest defence and security news from Janes - the trusted source for defence intelligence.

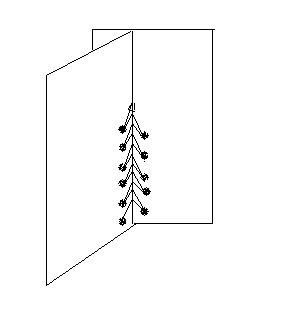

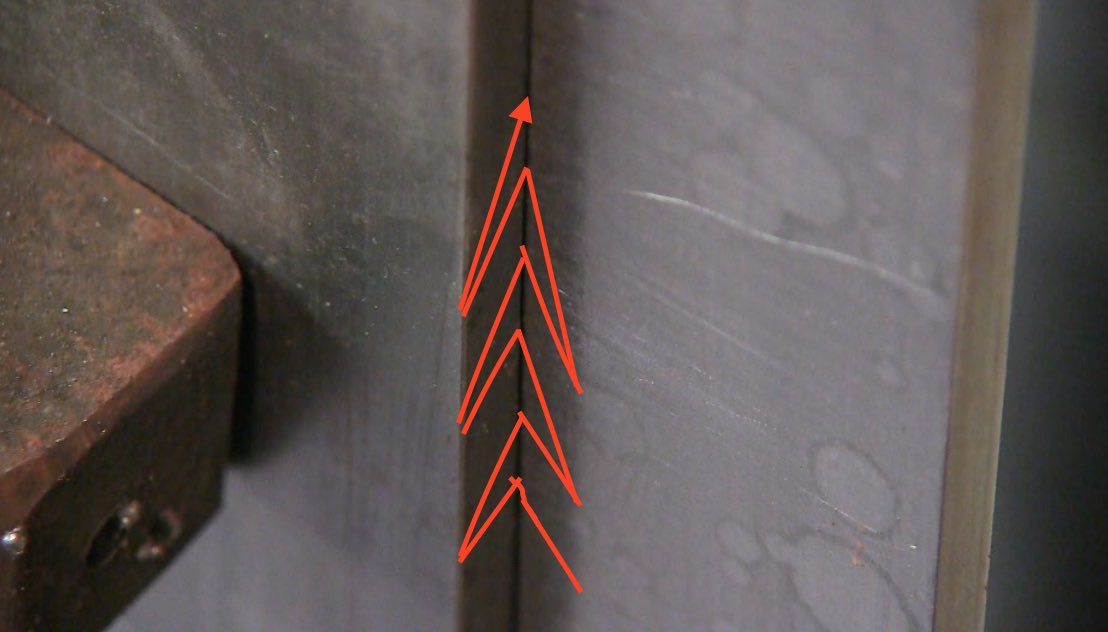

In addition to melting the base metal a filler material is typically added. TIG welding works well in all positions on almost any metal. When welding vertically Ive found that an inverted V welding style produces the most fill-out the most heat penetration and the deepest cuts into the metal but as suspected the crown of the weld gets a bit tall.

They can also be used to execute flawless pattern work or joining work like dadoes and rabbets. If the base metal does not retain enough clearance in assembly the base metal on both sides may touch together because of rotational deformation resulting in bending deformation or overlap and eventually. Overhead MIG Welding Techniques.

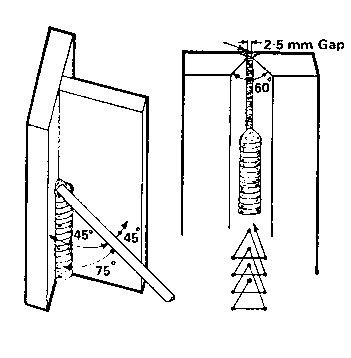

The electrolyte is a solution of a salt of the metal to be coated. MIG welding vertical up technique require the nozzle point upward 35 to 45 degrees. With the ability to achieve these finishes and more its no surprise these tools are a household name for woodworkers.

As with all MIG welders the push-style welding produces the best welds for this welder as it creates a hotter weld than the pull-style it is a 110 volt welder after all. Overall 46 of Mortiser buyers enquire on only used listings 54 on new and 552 on both new and used Mortiser itemsBuyers usually enquire on 196 different Mortiser classifieds before organising finance. Overhead MIG welding requires the MIG gun tilted 5 to 35 degrees toward the direction of the weld.

And the anode positive electrode is usually either a. Inspiring Growth and Success with quotes and life advice to help you succeed grow and achieve your goals. Shimming the bearing caps does the rest as far as setting the bearing clearance.

New and Used Mortiser insights. Just like any other welding process there is not a single pattern or way to make a good weld. Claudio Allevi Guido Collodi in Integrated Gasification Combined Cycle IGCC Technologies 2017.

1252 Liquefied gas storage. Many MIG welders do not weave or use a pattern. The only differences between a flat horizontal vertical and an overhead weld is how you mentally approach the task.

Powerhorse HorizontalVertical Electric Log Splitter 8-Ton 15 Amp 120V Motor. Electroplating is a general name for processes that produce a metal coating on a solid substrate through the reduction of cations of that metal by means of a direct electric currentThe part to be coated acts as the cathode negative electrode of an electrolytic cell. There are 39 Mortiser for sale in Australia from which to choose.

To create fuller penetration welding with the 6010 rod the welder should whip the electrode with 332 12 inch distance and immediately pull in back around 18 inch and then pause for split of a second to allow the rod to establish the weld puddle on the spot and whip forward and pull backward with the same movement pattern. A more recent trend is the MIG like TIG craze. It has a higher density and fewer potential risks in terms of storage pressure compared with the compressed gas.

This gives enough meat to turn new journals at 20625 nominal maybe a couple of thousandths under that. You want the heat to be on the hot side and once you do it for a while it is as easy as flat. Welding rotational deformation results from the welding gap of the weldments in front of the molten pool decreases with the welding process due to the thermal expansion.

10 Sep2019 - Woodworking routers are a commonly found tool used to make cuts create edging joinery and hollow out wood. If you have any interest in purchasing a kit version of this machine please click the above button and complete the form so that I can gauge the level of interestThis instructable will show you how to construct a CNC Router that will allow you to. The welding is done using either TIG or MIG and the as-welded diameter is 2 18.

This Vertical Mig Welding Technique Will Penetrate

Smaw Weave Patterns Google Zoeken Soldadura Mig Proceso De Soldadura Proyectos De Soldadura

Solid Wire Vertical Up Miller Welding Discussion Forums

Best Mig Welding Techniques For Everyone

Vertical Uphill Welding Technique

0 comments

Post a Comment